An automated gate system acts as the entry point to your property, supporting access control, daily convenience, and curb appeal. For a homeowner, reliable operation helps the exterior feel more polished while supporting a safer routine. When the system runs smoothly, opening and closing stay steady, and your gate delivers long-term durability through daily use and changing weather conditions.

Maintenance is what keeps that performance consistent. Regular maintenance reduces wear on parts, ensures smooth travel, and maintains safety sensors responsive throughout each cycle. Homeowners often ask how often professional service is needed. In most cases, a schedule based on gate style, automation features, and cycle rate helps reduce unexpected downtime and supports reliable operation throughout the year.

Maintenance Schedule Guidelines by Usage Level

Most residential automated gate systems benefit from professional inspection every 6–12 months. If the gate serves as the primary entry point and cycles frequently, every 6 months is a more dependable interval for stable performance and sensor reliability. Common issues that require gate repair in residential properties include malfunctioning motors, damaged gate tracks or hinges, sensor failures, and control panel or remote access problems. Regular maintenance helps identify these issues early, preventing costly repairs and ensuring reliable operation.

High-cycle residential entries (shared private lanes, frequent deliveries, multiple daily guest entries) often benefit from professional inspection every 3–6 months, depending on operator load and site conditions. Commercial entries typically require monthly to quarterly service depending on traffic flow, gate weight, and exposure.

For a clear breakdown of what’s happening inside the system during each open-and-close cycle, read What Are Automated Gate Systems and How Do They Work?

Understanding Automated Gate Systems and Their Maintenance Needs

An automated gate system integrates the gate, automatic gate openers, safety sensors, and a control unit to enable access control. These parts work together so a homeowner can open or close the entry point with minimal effort. When the system is correctly installed and calibrated, daily operation stays smooth and consistent.

Over time, regular use and weather conditions wear down moving and electrical parts. Regular maintenance helps keep alignment stable, supports durability, and reduces the risk of sudden failures that can weaken access control. Skipping scheduled checking can lead to damaged parts, unreliable closing, and more frequent repairs.

A practical maintenance routine also protects performance details that can drift over time, such as auto-close timing, operator sensitivity, and consistent latch engagement. When these settings shift, the gate may still move, but it can become slower, noisier, or less secure. Routine inspection helps keep the operation predictable and reduces strain on parts.

How Gate Automation Influences Service Frequency

The gate automation setup you choose affects how often the system needs professional checking. A basic setup with only a remote typically has fewer access-control parts, while systems with keypads, intercoms, smartphone control, vehicle detection loops, and multiple safety sensors have more parts that can drift out of alignment or require calibration over time.

Professional installation helps the system start strong, but regular maintenance still matters. Service visits often include calibration, safety sensor testing, and operator checks to ensure consistent movement and prevent minor issues from escalating into major failures. Many residential systems remain reliable with 6–12-month service intervals, while high-use and commercial entries may require more frequent checks.

Automation accessories also affect service needs, as each added feature introduces wiring, connections, and settings that require periodic inspection. Keypads and intercoms can develop signal or power issues, and smart controls may need updates or network troubleshooting. When the system includes more accessories, a consistent service schedule helps ensure every access method remains reliable.

Important Gate Parts Requiring Regular Maintenance

Several key parts of an automated gate system need routine inspection to keep the operation reliable and safety features responsive. When these parts are not checked regularly, performance can decline, leading to uneven movement, inconsistent closing, or sensor errors that often result in repair calls.

During a maintenance visit, a technician will test the operation, verify alignment, and apply appropriate lubrication as needed. Regular checking helps reduce wear, improve durability, and lower the chance of sudden failures.

Another area that deserves attention is the gate structure and mounting points. Posts, brackets, and weld points can loosen over time, especially as the system cycles through daily movement and seasonal temperature shifts. Routine inspection helps confirm that the gate remains level, the hardware remains secure, and the operator is not under unnecessary tension from shifting alignment.

Operator and Moving Parts

The operator does the heavy work, and the drive parts absorb repeated loads every day. Hinges, rollers, chains, belts, and gear racks also carry constant tension during each cycle. Proper lubrication (using the right lubricant for the application) helps reduce friction, limit wear, and support smoother movement. A technician will also inspect for vibration, unusual noise, and uneven travel that can signal early wear.

For swing gates, hinge wear can cause sagging and inconsistent latch alignment. For sliding gates, track condition and roller health affect smooth travel and consistent closing. If the gate hesitates, drifts, or shudders, the operator may be compensating for resistance, which increases strain on parts over time.

Sensors and Safety Devices

Safety sensors help reduce the risk of damaged vehicles or property at the entry point. Photo-eye sensors must stay clean, aligned, and properly positioned. Safety edges, if installed, should be tested so they respond quickly. Many systems also rely on obstruction detection inside the operator, which needs calibration to match gate weight and movement resistance.

A technician will verify stop-and-reverse behavior and confirm the system responds consistently. When sensors are dusty, misaligned, or exposed to moisture intrusion, the gate may refuse to close or may behave inconsistently.

For a focused guide on the safety devices that matter most and how they protect your entry, read What Safety Features Should an Automated Gate Have?

Access Control Parts

Keypads, remotes, intercoms, vehicle detection loops, and smartphone control modules benefit from periodic checking. Batteries in remotes, wiring connections, antenna placement, and keypad weather seals can influence reliability. A technician will also confirm that each access method triggers the operator and that safety logic remains active throughout the cycle.

If the system uses smart controls, network stability can influence performance. When access methods become inconsistent, targeted inspection can identify whether the cause is power supply stability, wiring integrity, signal strength, or programming.

For a basic definition and operation overview of magnetic locks used in access control, read Wikipedia’s electromagnetic lock overview.

Factors That Affect Automated Gate Maintenance Frequency

Every automatic gate system has different service needs based on design, usage, and site conditions. Understanding what drives wear helps a homeowner plan a practical maintenance schedule and reduce surprise issues.

Key factors include gate material, the gate cycle frequency, and local weather conditions. In St. Louis, seasonal temperature swings, moisture, and winter conditions can increase wear on moving parts and electrical parts compared to milder climates. When service timing matches real-world use and environmental conditions, the system tends to be more reliable and consistent.

Gate size and operator load also influence service frequency. Heavier gates, wider spans, and gates exposed to strong wind can increase tension on moving parts and require the operator to work harder per cycle. Over time, that added strain can speed up wear on hinges, rollers, tracks, and drive parts, making more frequent inspection and calibration a smart choice.

For driveway gate layout and automation examples, Family Handyman’s driveway gate ideas roundup shows common styles homeowners use.

If you want to compare swing, sliding, and specialty layouts for driveway fit and long-term upkeep planning, read Which Types of Automated Gates Are Suitable for Your Driveway?

Gate Material and Frame Design

Material choice affects both durability and the rate at which service needs develop. Metal gates can deliver strong security, but protective coatings must remain intact to reduce corrosion. Wood gates can shift with moisture exposure, which may alter alignment and increase resistance. Vinyl resists corrosion, but extreme cold can reduce rigidity and may cause cracking if the frame is not reinforced.

Frame design also matters. A gate with wide panels can catch the wind, increasing resistance during movement. When wind load rises, the operator works harder, and service intervals often need to be tighter to keep the system operating consistently.

Cycle Rate and Daily Use

Cycle rate is one of the strongest predictors of service frequency. A gate that opens and closes a few times per day experiences slower wear than a gate that cycles repeatedly during school drop-offs, deliveries, shared driveways, or frequent guest access. High cycle rates increase wear on rollers, hinges, and operator drive parts, and they can also raise the risk of sensor drift over time.

If the gate is used as a primary entry point multiple times per day, service every 6 months is typically the safer schedule. If it cycles frequently, a technician may recommend checking every 3–6 months to ensure calibration, alignment, and safety sensor response remain consistent.

Site Layout and Driveway Conditions

Slope, drainage, and driveway layout can influence wear. Sliding gates need stable alignment and a clear travel path. If gravel, soil, or runoff accumulates near the travel area, it can raise resistance and reduce smooth travel. Swing gates require stable posts and properly aligned hinges, especially on properties with shifting ground or freeze-thaw cycles.

Entries near sprinklers or drainage runoff can also increase moisture exposure near electrical parts. When water intrusion is more likely, more frequent inspections help reduce intermittent faults and support long-term reliability.

Maintenance Interval Recommendations by Property Type

Homeowners want a clear schedule. While every property is unique, service timing usually follows predictable patterns based on cycle rate, gate size, and weather conditions.

Typical Residential Schedule

For many residential automated gate systems, professional service every 6–12 months supports reliable performance. A visit typically includes inspection, lubrication where needed, safety sensor testing, access control testing, and calibration checks. It also helps identify early wear in hinges, rollers, operator-drive parts, and mounting hardware.

If the gate cycles frequently, serves as the primary entry point, or is exposed to harsh weather conditions, a 6-month cycle is often more reliable. Semiannual inspections are invaluable for heavier gates, wind-exposed entries, and sites with higher moisture exposure.

High-Use and Shared-Access Residential Entries

Some residential gates function more like light commercial entries, such as shared private lanes or multi-home access points. These gates should be inspected by a professional every 3–6 months, depending on operator workload and debris exposure. A technician may recommend timing based on observed wear trends and site conditions.

Commercial Schedules

Commercial gate automation systems often require monthly to quarterly maintenance, depending on traffic flow. These systems must support consistent access control and reliable closing throughout repeated cycles. More frequent service helps maintain sensor response, keeps operator calibration accurate, and reduces downtime that disrupts operations.

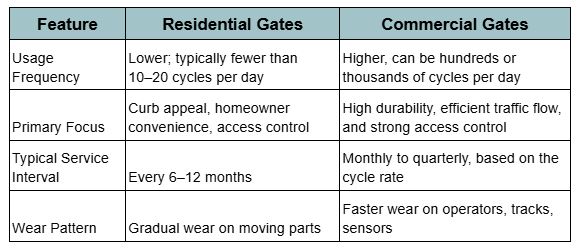

Residential vs. Commercial Gate Maintenance Requirements

Residential and commercial automated gate systems have different service needs because cycle rates and operating demands differ. Residential gates usually open and close fewer times per day, so wear on parts happens more gradually. Maintenance often focuses on smooth movement, consistent closing, and keeping safety sensors responsive while supporting curb appeal and daily convenience.

Commercial gates often undergo far more cycles per day, especially at busy facilities. That higher use increases wear on the operator, tracks, rollers, hinges, and safety devices. Because consistent access control and traffic flow matter, commercial systems typically require more frequent inspection, calibration, and wear planning. A consultation with a technician can help match service intervals to cycle rate and site conditions.

Weather, Usage Patterns, and Local Conditions in St. Louis, MO

In St. Louis, an automated gate system must handle significant seasonal shifts. Summer heat and humidity can affect electronics and accelerate corrosion, while winter ice and cold can stiffen movement and increase tension on moving parts. Temperature fluctuations can cause materials to expand and contract, which may affect alignment and lead to uneven operation if regular checks are skipped.

Material choice plays a significant role in durability under these conditions. Wood can warp or rot with prolonged exposure to moisture; metal can rust if protective coatings wear down; and vinyl generally resists moisture but may become brittle in extreme cold. Keeping the travel area clear of leaves, dirt, and snow, along with routine inspection for corrosion, worn parts, and sensor alignment, helps reduce downtime and supports more reliable operation after a repair.

Usage patterns can amplify weather-related wear. A gate that cycles many times per day in wet or freezing conditions is more likely to experience faster wear in rollers, hinges, and operator drive parts, especially if debris builds up in the travel path. If the entry is in direct sun, near sprinklers, or near drainage runoff, moisture exposure can increase the need for more frequent inspection and preventive service.

Seasonal Planning That Supports Reliability

A pre-winter inspection can help confirm that the operator runs smoothly in colder conditions, that safety sensors remain aligned, and that latch alignment remains consistent. A spring inspection can address corrosion, debris buildup, and alignment shifts from freeze-thaw cycles. Seasonal service also helps verify battery backup reliability under extreme temperature conditions.

Routine Maintenance Tasks Homeowners Can Handle Between Service Visits

Professional service is essential for calibration and detailed inspection, but a homeowner can also reduce wear with simple routines. These steps support cleaner operations and help detect early warning signs before they escalate into major repairs.

Keep the Travel Area Clear

Sliding gates require a clear travel path, and swing gates require consistent clearance throughout the arc of motion. Remove leaves, branches, dirt, gravel, and snow from the movement zone. Debris increases resistance, raises operator load, and can reduce smooth travel.

Clean Sensor Lenses and Check Mounting

Photo-eye lenses should be kept free of dust and residue. A gentle wipe with a soft cloth can help maintain responsiveness. Also, confirm that sensor brackets feel stable. If a sensor shifts, it can drift out of alignment, causing inconsistent closing.

Listen for Changes in Operation

New sounds often appear before a failure. Grinding, squealing, or clicking can signal wear, misalignment, or insufficient lubrication. If movement becomes slower or uneven, professional inspection can identify the cause before damage spreads to more parts.

Confirm Consistent Latch Engagement

If the gate does not latch consistently, access control is weakened. Latch misalignment can result from hinge wear, post shifting, or operator limit drift. A technician can recalibrate travel limits and confirm alignment to ensure the gate closes securely.

Warning Signs That Maintenance Is Overdue

Maintenance timing is not only calendar-based. Changes in operation often indicate the system needs inspection sooner than planned.

- Inconsistent closing or reversing: Sensor alignment, obstruction-detection calibration, debris buildup, track issues, or hinge wear can cause this behavior.

- Slower movement or hesitation: Resistance may be increasing from worn rollers, track alignment drift, hinge tension, or drive part wear.

- Access control delays: Wiring integrity, power supply stability, or signal strength can affect response.

- Visible corrosion or wear: Rust, cracked seals, and frayed wiring indicate inspection is overdue.

What to Expect From Professional Automated Gate Services

When scheduling professional automated gate services, expect a detailed inspection rather than a quick surface check. A technician should evaluate the operator, hinges or rollers, track condition, and access control parts, then test movement through complete open-and-close cycles. Typical service includes applying the correct lubrication to moving parts, checking battery backup performance, and confirming safety sensors are aligned and responsive.

A thorough consultation should assess the current system condition, identify worn parts, and outline preventive measures to support reliability and clear communication, including the work to be completed and the expected results after service.

A strong service visit also includes calibration and performance verification. The technician should confirm travel limits, sensitivity settings, auto-close timing, and latch engagement to ensure the gate closes securely and operates consistently.

Gate Maintenance Plans and Emergency Repair Solutions

Choosing a regular gate maintenance plan versus waiting for a problem often comes down to reliability. A planned schedule supports consistent operation by catching wear early, keeping safety features responsive, and reducing unexpected downtime. Routine inspection also helps extend durability by reducing excess tension on moving parts and keeping operator settings calibrated.

Emergency repair service is essential when the gate will not open or close, or becomes stuck in a position that compromises access control. A rapid response helps restore access control and reduces the risk of additional damage to components from repeated cycling of a strained system.

A maintenance plan typically includes:

- Lubrication of moving parts to reduce friction and wear

- Inspection and testing of safety sensors and access control parts

- Minor adjustments and calibration to support smooth, reliable movement

Regular maintenance helps an automated gate system remain reliable, extend its service life, and support safer access control for homeowners. Routine inspection, proper lubrication, and safety sensor testing reduce wear on parts and help prevent sudden failures that interrupt daily entry. When service timing aligns with the cycle rate and local weather conditions, the system is more likely to operate smoothly through seasonal shifts and peak-use periods.

Guardian Door & Gate provides professional automated gate services, including maintenance planning and emergency repair support for St. Louis homeowners. If you want help building a service schedule or need a technician to inspect your system, contact us or call today to schedule a consultation.

Frequently Asked Questions

How often should automated gate systems need maintenance?

Most residential systems benefit from professional service every 6–12 months. High-cycle residential entries often need checking every 3–6 months. Commercial entries commonly require monthly to quarterly service depending on cycle rate, gate weight, and exposure.

What is included in professional automated gate maintenance?

Maintenance commonly includes inspection of moving parts, lubrication where appropriate, safety sensor testing, access control testing, battery backup checking, and calibration of operator settings. Mounting hardware and alignment are also checked to support consistent closing.

What warning signs mean maintenance is overdue?

Slow movement, unusual noise, inconsistent closing, unexpected reversing, or access control delays are common signs. Sensor errors and incomplete latch engagement also indicate that the system requires inspection to reduce strain on parts and restore reliable operation.

Do automatic gate openers require lubrication?

Many moving parts require lubrication, but application points and product type depend on gate style and operator design. A technician can apply the appropriate lubricant where needed and confirm smooth travel with no residue buildup.

Can weather conditions in St. Louis change service timing?

Yes. Heat, humidity, ice, and freeze-thaw cycles can increase wear and affect alignment. Seasonal inspection supports responsive sensors, reliable closing, and consistent operator performance through temperature swings.

Do smart gate accessories increase maintenance needs?

Often, yes. Smart controls, keypads, intercoms, and additional sensors introduce more wiring and settings that require periodic inspection and maintenance. Routine service helps reduce intermittent signal or power issues and keeps access methods consistent.

What can a homeowner do between service visits?

Keep the travel area clear, clean sensor lenses gently, and monitor latch engagement. Listen for new noises or slower travel. If operation changes, schedule a professional inspection before the strain spreads to additional parts.

How long can an automatic gate opener last with regular maintenance?

Many openers last around 10 to 15 years, depending on cycle rate, gate weight, and site exposure. Routine inspection and calibration, along with timely replacement of worn parts, can extend service life.

Is annual maintenance enough for high-use residential gates?

Some high-use residential entries benefit from being checked every 6 months, or every 3–6 months when the cycle rate is high. Timing depends on operator load, site exposure, and debris patterns near the travel area.

When should emergency automated gate repair be scheduled?

Emergency service is appropriate when the gate is stuck open or closed, fails to secure the entry point, or exhibits sudden failures that prevent safe operation. A rapid response helps restore access control and reduces the risk of additional damage.